Retrofit of a food production line in Montreal

America

Robotics, an accomplished ecosystem for Newrest

Newrest is already a strong actor in robotics and especially in Cobotics development. Cobotics is the collaboration between humans and robots at work.

At the start, it took the deployment of more than 15 lines of cobots (collaborative robots) around the world to identify an ideal model that would generate productivity. A primary key step was taken with the creation of the universal robotic hand, which allows the gripping of any type of object, regardless of its container. But it is the integration of the employees as close as possible to the machine that brought the expected result.

Today, Newrest has already developed Cobotics in several areas. In Montreal, the system has been reviewed and improved.

How Newrest in Montreal has updated his assembly line process?

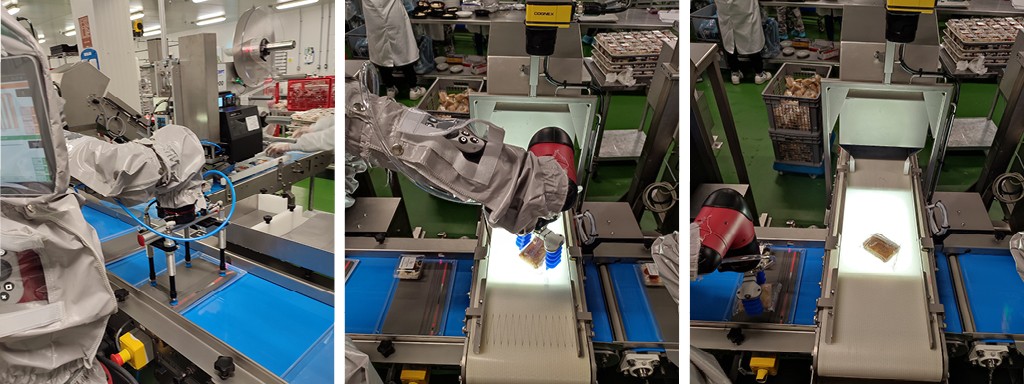

At first, the modification of the food assembly line was done by updating the robot programs. Then, the grippers were modified and conveyors were added. There’s also an implementation of a 2D unscrewing system, completed by a modification of the manufacturing process.

With collaborative robotics at Newrest

The operator works within the robot’s field of operation without the need for additional safety systems. Newrest has chosen Cobotics so that the robot is integrated into the operator’s environment and not the other way around. This is a perfect example of collaborative robotics at Newrest.

A 2D vision system with backlighting

A 2D backlighting system has been integrated for a simple and efficient system. The implementation of a bun unscrambler solution was installed. The latter is equipped with a 2D vision system using a Cognex camera and backlighting, combined with a gripper system using Soft Robotics.

New robotic labelling and gripping process for fragile products

An in-line printer and a Soft Robotics gripper make it possible to eliminate tedious steps in the assembly of meal trays for the Newrest group. Teams have control over the gripper, including opening, closing and force parameters to grip fragile products. The rubber is suitable for gripping food.

It is always good challenge for Newrest to improve itself in robotics.

en

en

fr

fr